Your Trusted Titanium Rod & Bar Supplier Since 2010

- Customized Titanium Bars in Various Grades and Sizes

- Large Inventory Available | Free Samples Provided

- High Strength, Excellent Corrosion Resistance, Long-Term Durability

- Factory Direct Pricing | ISO 9001 & CE Certified Quality

- 850+ Satisfied Customers Worldwide | Complete After-Sales Support

Send inquiry to get a free sample

Our Featured Titanium Bar Products

We specialize in manufacturing high-quality Titanium Rods and Bars, available in various shapes including Round Bars, Flat Bars, Square Bars, and Hex Bars. Whether you need standard sizes or custom specifications, we deliver products tailored to your exact requirements. Trusted by over 500 satisfied clients worldwide, every titanium rod and bar is precisely crafted, strictly quality-tested, and ready for fast global delivery.

Customized Titanium Bar Specifications

| Grade | Gr1, Gr2, Gr3, Gr4, Gr5(Ti-6Al-4V), Gr6(Ti-5Al-2. 5Sn), Gr7(Ti-0.12~0.25Pd), Gr9(Ti-3Al-2.5V), Gr12(Ti-0. 3Mo-0.8Ni), Gr23(Ti-6Al-4V ELI), Ti-6Al-7Nb, Ti-13Nb-13Zr |

| Standards | ASTM B348; ASTM F67; ASTM F136; AMS 4928; ASTM F1295; ASTM F1713; ISO 5832-2; ISO 5832-3 |

| Size | Round Bar Size: Dia 3.0 – 600mm*≤6000mm(Customization is acceptable) Square Bar Size: Width: 55-100mm Thickness: 2-300mm(Customization is acceptable) Flat Bar Size: Width: 10-300mm Thickness: 2-300mm*≤6000mm(Customization is acceptable) Hex Bar Size: Dia 3.0 – 600mm *≤6000mm(Customization is acceptable) |

| Technical | Hot Rolling |

| Condition | Annealed |

| Supply Status | R M Y |

| Shape | Ti Round Bar,Ti Square Bar ,Ti Flat Bar, Ti Hexagonal Bar |

| Tolerance | h5~h13,H6~H13 |

Our Titanium Rod Application

Why Choose Our Titanium Bars?

1. Full Grade Range for All Applications

From GR1 to GR5 and GR23, our titanium bars support everything from corrosion-resistant marine systems to aerospace-grade components.

🟢 Always get the right grade — without changing suppliers.

2. Delivered Ready to Use – No Extra Processing Needed

Bars can be cut to exact lengths and optionally polished, pickled, or CNC-machined to tight tolerances.

🟢 Save time and reduce rework on your production floor.

3. High Strength at Low Weight

Titanium is 45% lighter than steel with comparable tensile strength — perfect for aerospace, defense, and precision parts.

🟢 Reduce part weight without sacrificing durability.

4. Corrosion Resistance That Lasts

Our titanium resists saltwater, acids, and industrial chemicals — ideal for harsh operating environments.

🟢 Cut maintenance costs and extend service life.

5. Fast Global Shipping with Full Documentation

We maintain stock and offer short lead times, shipping globally with MTC and export documents.

🟢 Avoid project delays and receive materials ready for use.

6. Factory Direct – Competitive, Transparent Pricing

As a titanium bar manufacturer with 15+ years of expertise, we offer mill-direct pricing with no hidden markups.

🟢 Improve margins and control both cost and quality.

Contact Us to Get a FREE Sample!

Our mission is to reduce costs and increase efficiency for your titanium bar project!

Reliable Titanium Rod Manufacturer and Supplier

At Yunch Titanium, we understand the importance of sourcing high-quality titanium bars that meet your specific needs. Since our establishment in 2009, we have dedicated ourselves to manufacturing and supplying titanium bars with precision and expertise. With a decade of hands-on experience, we pride ourselves on delivering products that combine exceptional durability, lightweight design, and corrosion resistance—qualities essential for a wide range of industries.

As a trusted partner for global buyers, we prioritize your success by offering competitive pricing, reliable delivery, and personalized customer service. From initial consultation to final delivery, our team is here to ensure your procurement process is seamless and efficient.

Choose Yunch Titanium for titanium bars that exceed your expectations and support your business goals.

Brands & companies we worked with.

Yunch Titanium has collaborated with renowned brands and companies, delivering exceptional titanium bar products and solutions tailored to their unique requirements.

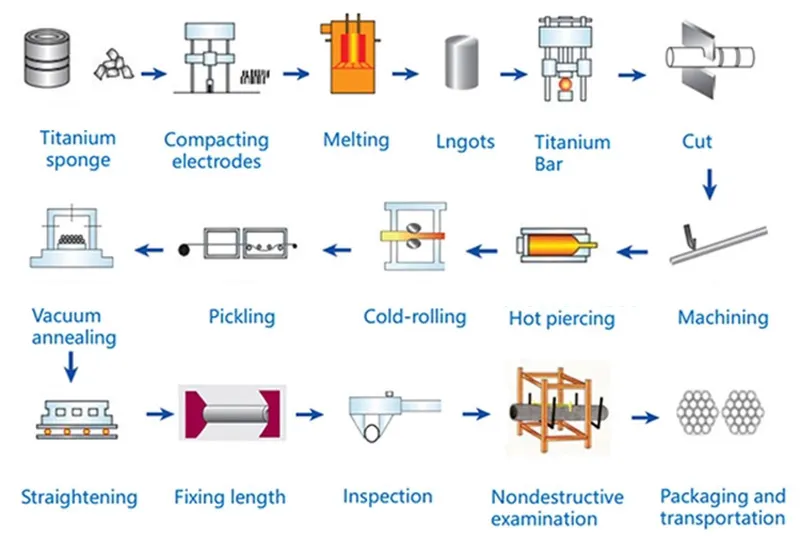

Professional Titanium Bar Production Process

- Raw Material Selection: Start with carefully chosen high-grade titanium ore or sponge to ensure the raw material’s purity and quality.

- Melting: Utilize a vacuum arc furnace to melt the raw titanium, resulting in a homogeneous ingot.

- Forging & Rolling: Heat the ingot and employ forging or rolling techniques to reduce its size and shape it into the desired bar or rod profile.

- Heat Treatment: Refine the microstructure and optimize the mechanical properties of the titanium through controlled heat treatment processes.

- Straightening & Finishing: Straighten the bar or rod and subject it to various finishing processes like turning, grinding, or polishing to achieve the specified surface finish.

- Quality Inspection: Thoroughly test each titanium bar and rod, including ultrasonic, visual, and dimensional checks, to ensure they meet the required standards.

- Packaging & Dispatch: Once approved, securely package the bars and rods for dispatch to be used in diverse applications across industries.

Technical Guidance

Not sure how to choose the appropriate titanium grade, such as (Gr1, Gr2, Gr3, Gr4, Gr5, Gr7, Gr9, Gr12, Gr23, Ti13Nb13Zr, Ti6Al7Nb). We have a professional technical team that will recommend the suitable titanium grade and titanium standard based on your application

Standardized Production

We have a comprehensive production quality management system in our factory. From the begining of titanium sponge to forging, rolling, hot drawing, straightening, peeling and until the final stage of finished titanium rods, all production processes are documented and traceable. Additionally, each batch is subjected to random sampling inspections for quality assurance.

Take a Look at Our Equipment

See What Our Clients Say

Frequently Asked Questions

We offer titanium rods in various grades, including Grade 1, Grade 2, Grade 5 (Ti-6Al-4V), and Grade 23 (ELI). These cover commercial pure titanium and titanium alloys to suit different applications such as aerospace, medical, chemical processing, and marine industries.

Yes, we support custom diameters, lengths, surface finishes, and machining according to your drawings or specifications. CNC machining, cutting, grinding, and polishing are available in-house.

Absolutely. All titanium rods come with Mill Test Certificates (MTCs) in accordance with ASTM B348 or other applicable standards. We also provide full traceability for every batch.

Our MOQ is negotiable, depending on your project requirements. For commonly stocked sizes, we accept small trial orders and even offer free samples for testing.

For in-stock titanium rods, we can ship within 3–5 working days. For custom orders, lead time is usually 7–15 days, depending on processing complexity and order quantity.

Yes. We offer free samples (within a reasonable size and value) – you only need to pay for the shipping cost. This helps you verify our quality before bulk purchasing.

We guarantee product quality and conduct thorough inspections before shipping. In the rare event of a defect, we offer full support, including replacements or refunds.

Titanium Rod Supplier Can be Easy & Safe

Regardless of the type of titanium bar product you need, our extensive experience allows us to manufacture it. In particular, since we produce our own raw materials, we can offer better pricing and quality control than our global competitors.

Address: No.128, Gaoxin Road, Baoji City, Shaanxi Province of China

Phone: +86 15091587124

Email: info@yunch.tech

Get a Free Titanium Bar Sample

Send inquiry to get a free sample